A diesel engine is an internal combustion power device that uses diesel to spontaneously ignite under high pressure and high temperature to generate energy, thereby driving the piston to move and output mechanical energy.

Diesel engines are widely used in various industries such as construction machinery, agricultural equipment, commercial vehicles, generator sets, etc. due to their high efficiency, durability, and fuel economy. Diesel engines are divided into many types according to different structural designs and usage requirements.

Classification by Stroke Number

These types depend on how they work: two-stroke and four-stroke diesel engines. Each type works differently and fits certain jobs.

Two-Stroke Diesel Engines

Two-stroke engines finish a power cycle in two piston strokes. This design gives them lots of power, perfect for heavy-duty tasks. You’ll see these engines in ships, power plants, and other big operations. They are small but strong, making them great for large-scale work.

For instance, a two-stroke engine can have 5.22 liters of displacement. It can produce 150 kW of power at 2800 rpm. This is useful for industries needing high power.

Four-Stroke Diesel Engines

Four-stroke engines are the most popular type today. They work in four steps: intake, compression, power, and exhaust. This design makes them smooth and fuel-efficient. They are used in cars, generators, and small machines.

At moderate speeds (3000-4000 RPM), four-stroke engines use less fuel. At higher speeds (above 4500 RPM), two-stroke engines save more fuel. Both types are efficient for regular use.

Four-stroke engines are reliable and flexible. They balance power and efficiency, making them great for everyday needs. Whether for a car or generator, they perform well.

Classifications of Diesel Engines by Design

Diesel engines are grouped by their design, which affects how they work. Two key design features are how they cool down and how fuel is added.

Cooling Method (Air-Cooled vs. Water-Cooled)

Cooling helps engines manage heat while running. There are two main types: air-cooled and water-cooled engines.

- Air-Cooled Engines: These use air to remove heat. They are simple and need less care. You’ll find them in small machines like motorcycles and portable generators.

- Water-Cooled Engines: These use liquid to control heat. They work better for heavy jobs like trucks and factory equipment. They stay cool even under tough conditions.

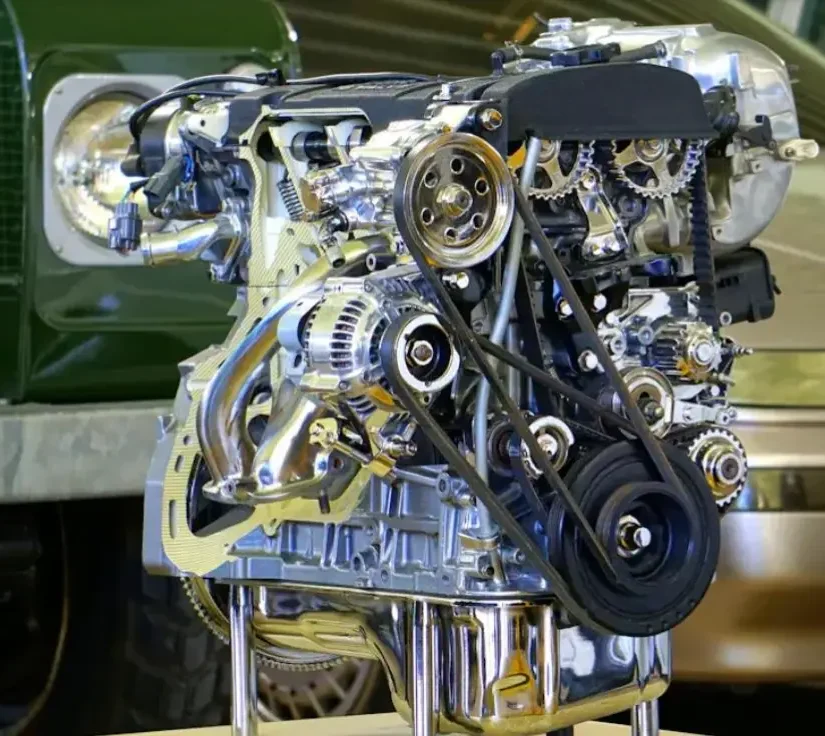

Fuel Injection System (Direct Injection vs. Indirect Injection)

Fuel injection controls how fuel enters the engine. This affects how well the engine performs.

- Direct Injection: Fuel goes straight into the engine’s combustion area. It gives better power and uses less fuel. Modern cars and trucks often use this system.

- Indirect Injection: Fuel first goes into a small chamber before the main engine area. This makes the engine quieter and smoother, good for smaller machines.

Classifications of Diesel Engines by Performance

Speed (High-Speed, Medium-Speed, Low-Speed)

Diesel engines are grouped by how fast they run. Their speed affects how they work and what they’re used for.

| Classification | Speed Range | Application |

|---|---|---|

| High-speed diesel engine | >1000 rpm | Generators, trucks, construction machinery |

| Medium-speed diesel engine | 300–1000 rpm | Marine auxiliary equipment, industrial power |

| Low-speed diesel engine | <300 rpm | Ultra-large ocean-going ships |

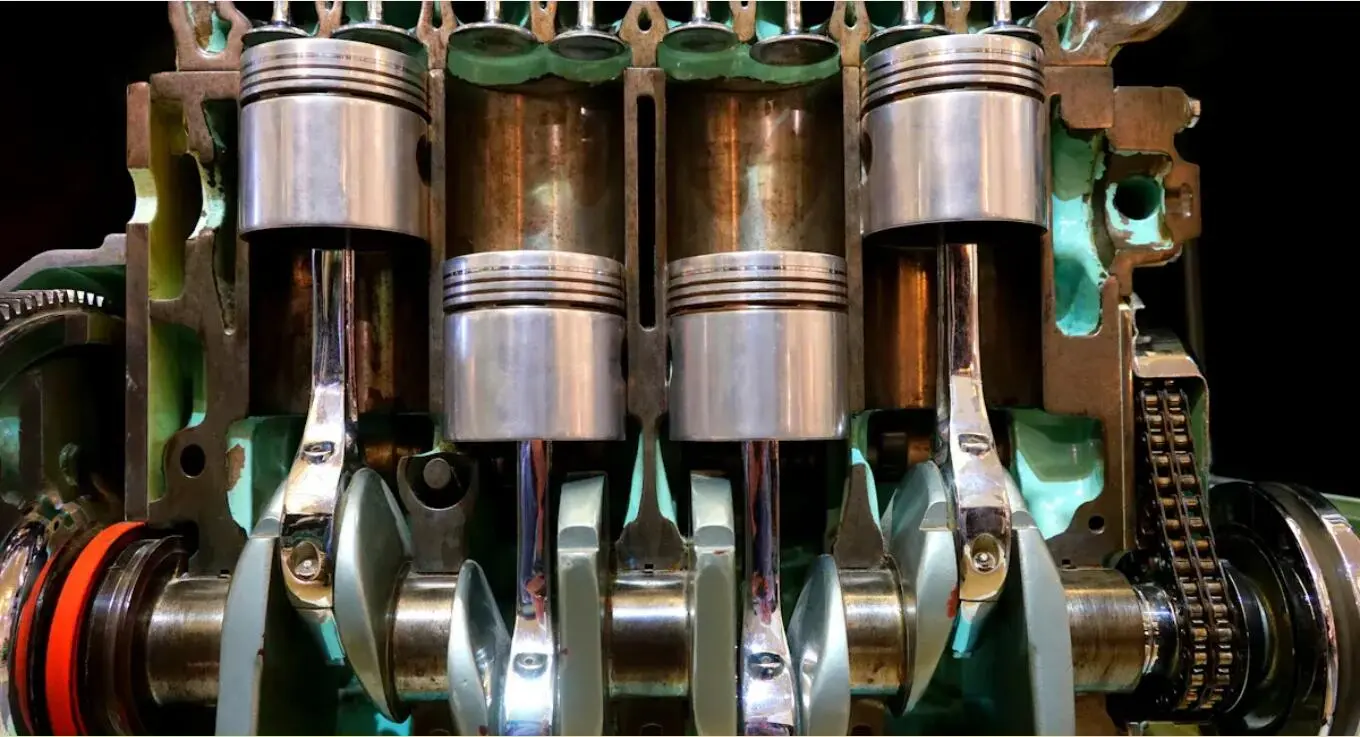

Classification by cylinder arrangement

In-line diesel engine

Features: The cylinders are arranged in a straight line, with a simple structure and easy maintenance.

Applications: small and medium-sized commercial vehicles, light engineering machinery, diesel generator sets.

V-type diesel engine

Features: The cylinders are arranged in a “V” shape, with a compact structure and strong power.

Applications: large trucks, ships, and large engineering equipment.

Horizontally opposed diesel engine (Boxer)

Features: The cylinders on both sides are horizontally symmetrically distributed, with stable operation and a low center of gravity.

Applications: Rare, used in some special vehicles or equipment.

Classification by number of cylinders

Single-cylinder diesel engine: commonly used in portable equipment, and small agricultural machinery, such as water pumps, and small tillers.

Multi-cylinder diesel engine (2 to 8 cylinders and above): used in medium and large equipment, such as excavators, tractors, trucks, marine main engines, etc.

Multi-cylinder design helps improve power output and running stability and is the mainstream structure of modern diesel engines.

Classification by intake method

Naturally aspirated diesel engine (NA)

Working principle: air enters the cylinder under atmospheric pressure.

Features: simple structure, easy maintenance, but low power output.

Turbocharged diesel engine (Turbocharged)

Working principle: using a supercharger to increase intake pressure and improve combustion efficiency.

Features: high output power, better fuel efficiency, suitable for high-load equipment.

Classifications of Diesel Engines by Application

| Type of use | Typical applications |

|---|---|

| Automotive diesel engines | Trucks, buses, pickups |

| Construction machinery | Excavators, loaders, bulldozers |

| Agricultural machinery | Tractors, harvesters, rotary tillers |

| Generator sets | Normal/standby diesel generator sets |

| Marine diesel engines | Fishing boats, cargo ships, propulsion systems |

Each purpose has different requirements for the power, speed, and durability of the diesel engine, and the selection needs to be matched according to the specific scenario.

Summary

Different types of diesel engines have their advantages. When choosing, you need to consider factors such as equipment type, power requirements, working environment, and economy. Understanding the classification of diesel engines not only helps to choose the right engine but also is an important reference for maintenance and replacement of accessories.

If you need to purchase diesel engine parts, repair kits, or technical support, welcome to check out Baileparts. We provide a full range of high-quality diesel engine accessories, support OEM/ODM customization, and cover multiple brands and models such as Yanmar, Kubota, Mitsubishi, Isuzu, Cummins, and Caterpillar.