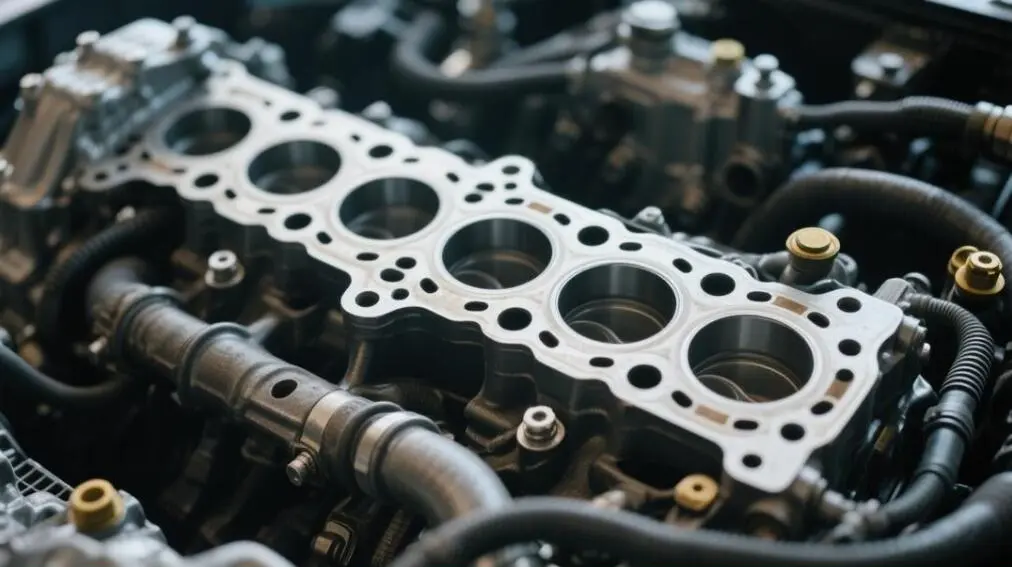

As an important part of the engine, the cylinder head of the engine has multiple functions such as sealing the combustion chamber, supporting the valve mechanism, withstanding high temperature and high pressure, and conducting coolant.

Due to its extremely harsh working environment, a damaged or cracked cylinder head will not only affect the engine’s performance but may also cause serious mechanical failure and increase maintenance costs. This article will analyze the common causes of cylinder head damage and propose effective maintenance and preventive measures.

The main reasons for cylinder head damage and cracking

1. Overheating

Overheating is the most common cause of cylinder head damage. When the engine works under long-term high temperatures or cooling system failure, the cylinder head material will deform or crack due to thermal expansion stress. In particular, the cylinder head made of aluminum alloy has a large thermal expansion coefficient and relatively weak high-temperature resistance, which is more likely to cause structural instability due to overheating.

The main causes include:

- Coolant leakage or loss;

- Failure of cooling system components such as water pump, radiator, thermostat;

- Fan failure or thermostat jamming;

- Long-term heavy load operation or working in a high-temperature environment.

2. Abnormal combustion pressure

If the combustion pressure in the combustion chamber is too high, for example, due to pre-ignition, detonation, or abnormal injection system, the cylinder head may be subjected to mechanical stress beyond the design range, which may cause cracks or fractures after long-term accumulation.

3. Improper installation torque

If the cylinder head bolts are under-torqued or unevenly distributed during installation, it will lead to poor sealing and local stress concentration, increasing the risk of crack formation. Over-tightening may also cause threaded holes or cover plates to crack due to excessive tensile stress.

4. Material defects or aging

Some cylinder heads are prone to premature failure under extreme conditions due to internal defects such as casting defects, pores, slag inclusions, or metal fatigue aging caused by long-term high temperature and high-pressure operation.

5. Scaling and blockage of the cooling system

If the coolant has not been replaced for a long time or an inferior coolant is used, it is easy to form scale or sediment, resulting in uneven local heat dissipation, causing local overheating, and then inducing deformation or even rupture of the cylinder head.

Maintenance and preventive measures

Proper cooling system maintenance:

It is essential to ensure that the cooling system is well maintained. This includes regularly checking and cleaning the radiator, ensuring that the coolant level is adequate, and changing the coolant at the recommended intervals.

Efficient cooling prevents overheating of the cylinder head and other engine components, which is essential to prevent cracks caused by thermal expansion and contraction.

Use of high-quality coolant:

Regular analysis of coolant and monitoring of corrosion inhibitors can prevent coolant degradation, which can cause overheating and possible damage to engine components.

For engines such as excavators and tractors, which are subject to heavy loads and harsh environmental conditions, implementing these measures is not only preventative but also cost-effective.

By effectively reducing cylinder pressure and managing temperature, operators can minimize the risk of cylinder head cracks and ensure the long-term durability of the engine.

This proactive approach not only improves equipment reliability but also reduces downtime and maintenance costs associated with premature engine failure.

Install to the specifications

When installing the cylinder head, a professional torque tool should be used, and the torque value and tightening sequence specified by the manufacturer should be strictly followed;

When replacing the cylinder gasket and bolts, original or high-quality accessories should be used to avoid poor sealing due to dimensional errors.

Conclusion

Understanding the root cause of cylinder head cracks and taking positive measures is essential to maintaining the performance and service life of diesel engines.

Once the cylinder head is damaged or cracked, it will not only lead to a decline in engine performance but also may cause serious mechanical failures, and increase maintenance costs and downtime risks. Through scientific and standardized use and maintenance, the risk of cylinder head damage and cracking can be greatly reduced, and the overall service life of the engine can be extended.

Especially for users of heavy-duty machinery, engineering equipment, and commercial vehicles, preventive maintenance is of greater significance. Only by always adhering to the concept of “prevention is better than maintenance” can the engine be guaranteed to operate efficiently, safely, and stably for a long time.