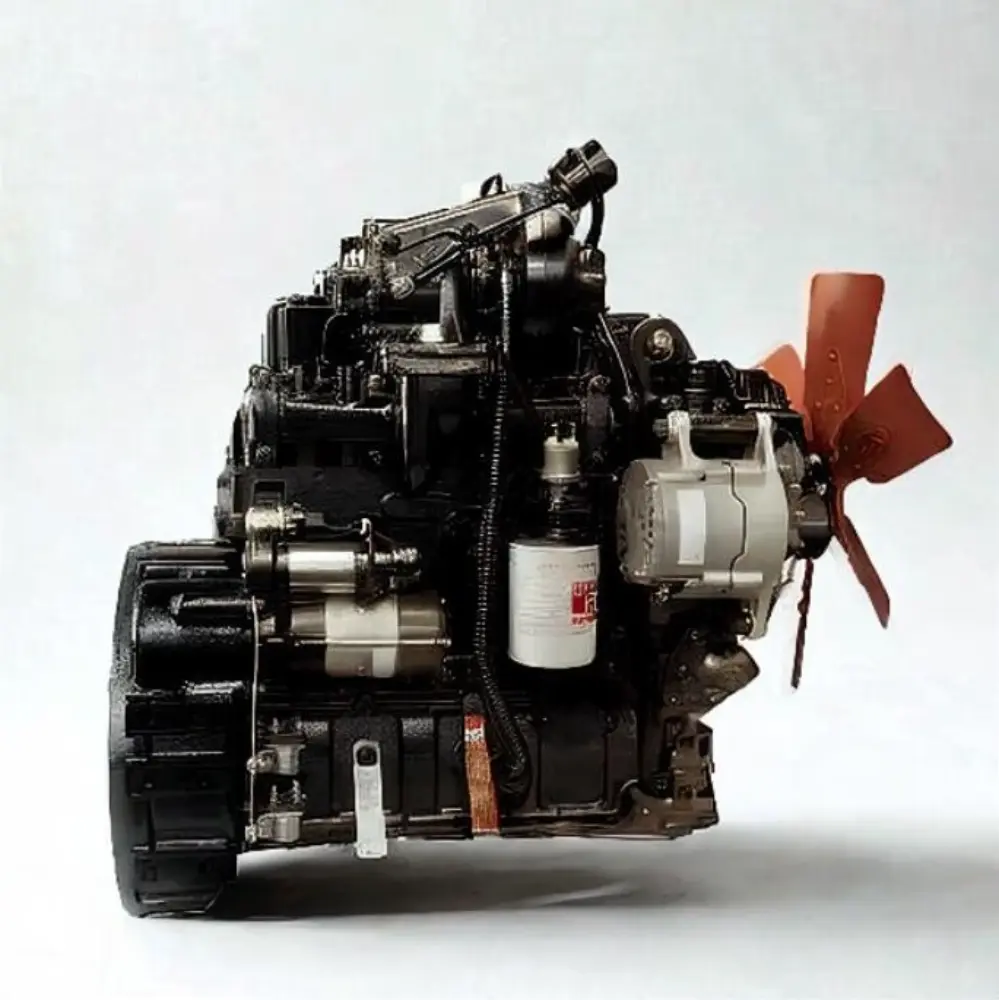

The Cummins 4BT is a classic representative of Cummins’ B-Series engine family. 4BT stands for “4-cylinder, B-Series, Turbocharged”, which means an inline four-cylinder, four-stroke, turbocharged diesel engine.

For its compact structure, high torque output, and easy maintenance, 4BT is widely used in construction machinery, commercial vehicles, generator sets, and industrial power equipment worldwide. Its good parts, versatility, and global after-sales support make 4BT the preferred power solution for many equipment manufacturers and repairers.

Cummins 4BT Engine Specifications

Configuration

The Cummins 4BT engine uses an inline 4-cylinder layout. This design helps the engine stay balanced and smooth during operation. The engine block and cylinder head both use cast iron, which adds strength and durability. The firing order is 1-3-4-2, and the engine uses an overhead valve (OHV) system with two valves per cylinder. The engine features a deep-skirt block, which means the block extends below the crankshaft centerline for extra rigidity.

| Specification | Details |

|---|---|

| Configuration | Inline 4-cylinder |

| Cylinder Head | Cast iron |

| Engine Block | Deep-skirt cast iron |

| Firing Order | 1-3-4-2 |

| Valve Train | OHV, 2 valves per cylinder |

| Aspiration | Turbocharged (4BT), turbocharged and aftercooled (4BTA), turbocharged and intercooled (4BTAA), naturally aspirated (4B) |

Displacement and Dimensions

The Cummins 4BT engine has a displacement of 3.9 liters, or 239 cubic inches. The bore measures 4.02 inches, and the stroke is 4.72 inches. These measurements help the engine produce strong torque at low speeds. The engine’s compact size allows it to fit in many vehicles and machines.

Displacement:3.9 liters (239 cubic inches)

Bore: 4.02 inches (102 mm)

Stroke: 4.72 inches (120 mm)

Engine Length:30.6 inches

Engine Width:24.6 inches

Compression Ratio:16.5:1 to 18.5:1

Power and Torque

The Cummins 4BT engine delivers a wide range of power and torque, depending on the model and year. Early versions, made before 1998, usually produced around 105 horsepower and 265 lb-ft of torque. Later models, especially those with aftercoolers or intercoolers, could reach up to 150 horsepower and 420 lb-ft of torque. This strong torque at low RPM makes the engine ideal for heavy-duty work.

| Specification | Details |

|---|---|

| Horsepower Range | 105-150 HP |

| Torque Range | 265-420 lb-ft |

| Compression Ratio | 17.5:1 |

| Fuel Type | Diesel |

| Emissions Standard | EPA Tier 1 or Tier 2 (varies by model) |

Fuel System

The Cummins 4BT engine uses a mechanical direct injection system. Most engines use a Bosch VE rotary pump, but some use the Bosch P7100 inline pump. This system delivers fuel directly into the combustion chamber, which improves efficiency and power. The engine does not need glow plugs for cold starts, which makes it easier to use in cold weather.

- Mechanical direct injection

- Bosch VE rotary or P7100 inline fuel pump

- Gear-driven injection pump

- No glow plugs required

Key Features

Durability

The Cummins 4BT engine stands out for its rugged construction and long-lasting performance. The engine block and cylinder head use cast iron, a material that can withstand high pressures and stresses, giving the engine exceptional strength. The simple mechanical design has fewer parts that can fail, making maintenance easier and less frequent.

| Material | Cast iron has excellent structural integrity and is able to withstand high pressures and stresses, ensuring engine durability under extreme temperatures and heavy industrial use. |

| Mechanical Design | Simple, minimal electronics reduce failure points and ease troubleshooting and maintenance. |

| Durability | The engine can endure repeated repairs and rebuilds without performance loss. |

| Longevity | With proper maintenance, the engine lasts beyond 300,000 miles. |

| Parts Compatibility | Shares durable parts with larger 6BT engine, enhancing rebuildability and aftermarket support. |

| Maintenance Accessibility | Straightforward design allows easier disassembly and reassembly, supporting long-term use. |

Fuel Efficiency

The Cummins 4BT engine delivers impressive fuel efficiency, which helps operators save money over time. Its high compression ratio and mechanical direct fuel injection system ensure that diesel fuel burns efficiently. Turbocharging further improves power output without wasting fuel. The engine produces peak torque at low RPM, which means it uses less fuel during heavy work or slow driving. This efficiency makes the engine a smart choice for businesses and individuals who want to lower fuel costs.

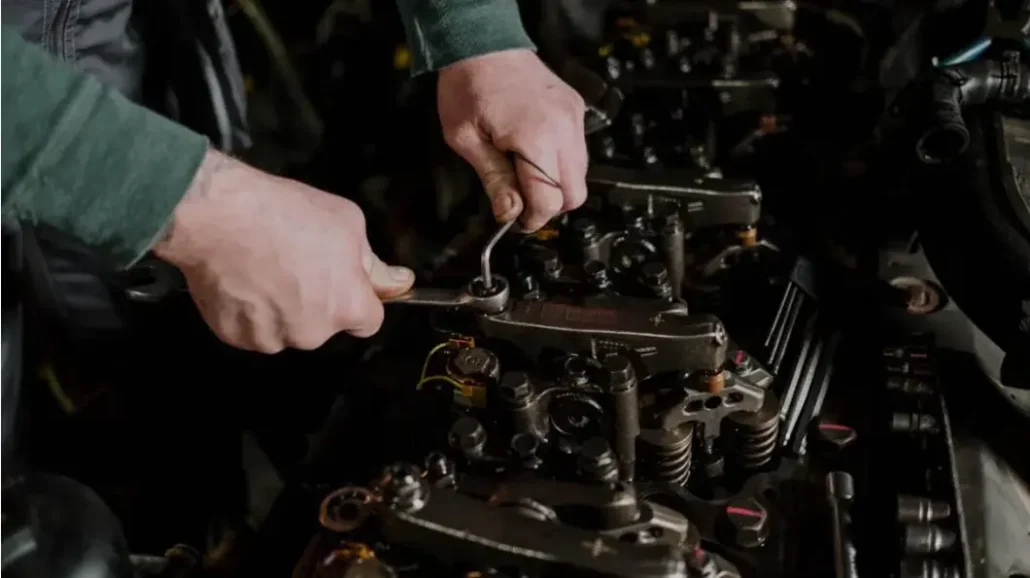

Mechanical Simplicity

Mechanical simplicity is a key reason why many people choose the Cummins 4BT engine. The engine uses a mechanical fuel injection system, which is easier to maintain and repair than modern electronic systems. This design allows routine tasks like oil changes and filter replacements to be done without special tools or computers. The engine’s straightforward layout also means fewer costly repairs and less downtime.

- Mechanical fuel injection system simplifies maintenance.

- Simple design lowers repair costs and reduces downtime.

- Favored in construction equipment and vehicle conversions for reliability.

1

Applications

1. Construction machinery and equipment

4BT is the main power source for many small and medium-sized construction machinery and equipment, including: small excavators, skid loaders, concrete pump trucks, small cranes, and road rollers

2. Commercial vehicles

4BT is also widely used in trucks, school buses, and light logistics vehicles, especially in North America, South America, Southeast Asia, and other regions.

3. Industrial power equipment

With its efficient and stable performance, 4BT is widely used in industrial power equipment: diesel generator sets (20-50 kVA), industrial air compressors, and engineering hydraulic power stations

4. Modification and replacement engine market

Due to its compact structure and strong output, 4BT is also popular in the modification market, and is often used for: off-road vehicle power upgrades, replacement of old mechanical engines, special vehicles, and off-road camp power systems

1

Maintenance

Service Intervals

Proper maintenance keeps the engine running smoothly and extends its life. Owners should follow the manufacturer’s recommended service intervals for best results. The Cummins B-Series Service Manual provides detailed schedules and technical instructions. Most experts recommend changing the engine oil and oil filter every 5,000 miles or 200 hours of operation. Air and fuel filters should be checked and replaced every 10,000 miles or 400 hours. Coolant levels need regular checks, and a full coolant flush should happen every two years. Valve adjustments are important and should be performed every 24,000 miles or as specified in the manual.

| Maintenance Task | Interval (Miles/Hours) | Additional Notes |

|---|---|---|

| Oil & Oil Filter Change | 5,000 / 200 | Use high-quality diesel oil |

| Air Filter Replacement | 10,000 / 400 | Replace sooner in dusty conditions |

| Fuel Filter Replacement | 10,000 / 400 | Prevents injector and pump damage |

| Coolant Flush | Every 2 years | Use the recommended coolant type |

| Valve Adjustment | 24,000 | Check the manual for the procedure |

Best Practices

Routine checks and good habits keep the engine reliable. Operators should inspect air and fuel filters often to prevent contamination. Monitoring coolant levels and flushing the system removes salt and debris, which helps avoid overheating. Mechanics recommend checking the turbocharger and fuel injectors for signs of wear or performance loss. Using high-quality aftermarket parts ensures the engine stays efficient and reduces downtime.

- Inspect water pumps, seals, and gaskets for leaks.

- Clean heat exchangers and oil coolers to maintain cooling.

- Monitor the thermostat to prevent overheating.

- Check the electrical system, including the battery and wiring.

- Inspect the exhaust system for leaks and emissions issues.

- Store the engine properly during long periods of inactivity to prevent corrosion.

- Schedule regular professional inspections to catch small problems early.

If you are looking for reliable 4BT engine assemblies and accessories or related repair solutions, please contact us! These parts can be genuine quality parts, original assemblies, or aftermarket replacement parts.

Visit Baileparts, enter the engine model or part number you need, and quickly find matching products.